Harpoon IPA

In August, I purchased a new 15gal single-tier brewing system. This is the first batch to go on that system, to learn how it works. Went with the Harpoon IPA from Clone Beers as it’s simple and a pretty good beer.

Brewer’s Notes

Learning a new system, so brew took a long time. Shortened the boil time from 90 to 60 minutes, so we ended up with more wort than expected, which lowered yield and IBUs.

Timeline

11:20a – put water on, 8 gallons at about 70F.

1:03p – mash water to temperature, 163F Mashed in 4.25 gal

1:10p – mash started, 90 minutes. Temperature dropped from 154 to 146 quickly, and settled at 146-143F through the mash. This is excellent, but low.

2:40p – Lit water for sparge at 1:55p, expecting 45 minute ramp time. Water started at 110F, so it only took 35m. Mash done.

3:05p – Sparge done, took about 25m for a two-step batch sparge. Recirculated about 2qts, then pumped. Added 2gal water, recirc and pump, then added 4.25gal water, then pump. Boil volume was 8.5gal. 2.5gal left in HLT.

3:50p – Water at temp, boil started for 60m

4:55p – started chilling. Outflow temp was 81F, but an error with the valves allowed unchilled wort, raising the final fermenter temp to 90F. Used 10gal water to chill

5:10p – Transfer and aeration completed, 1min O2. About 1.5gal left in the tank

6:00p – Kitchen cleaned and put away. Brew time was 6.5h

Important notes

- Strike water took 100min to go from 70 to 163F (90 deg)

- Mash held temperature well, but we lost 15F to the cooler – need to preheat

- Step-up time to boil was 45m for 8.5gal

- Chilling was about 1:2 ratio. Should be able to get that down

Beer is too light in color and taste – more of a light amber, softening to straw once the solids drop out. Tastes more like a malt tea, the low gravity shows here. Bitterness is OK. Fuggles hops show up heavily in flavor, aroma is light. The Aroma hops went in at 3minutes left, instead of the planned 1 minute. We will need to see how it ferments out – likely more of a session IPA, hopefully concentrates enough. Oxygenated for 1 minute, and set target ferment temp at 70F. Fermentation is expected to be warm at start due to the extra hot wort that was pumped into the fermenter.

Took 2 samples of the wort, one before boil and one after. The wort before the boil was 1.048 @ 142f, which I think was the first running only. This would create a 1.062 wort after temperature compensating, which would be correct. After sparging to 8.5gal, and then boiling, the next reading was 1.037 temperature-compensated, which is way too low. This is likely due to a smaller boil-off than expected and running too much sparge water through. Need to correct this by reducing sparge water amount and taking more measurements of the OG coming off the grain. (need a QR tee to splice inline?)

Unfortunately, this means that calculating efficiency is tough – it’s going to show up really low. (About 45%, but the batch sparge lowers this significantly)

About 4 additional gallons were used to clean equipment, this should be recoverable from cooling water using an empty keg, or the old bottling bucket.

OG: 1.034 @ 94F, target 1.062 (not sure about this)

FG: 1.0xx @ xxF, target 1.016

Fermenting Notes

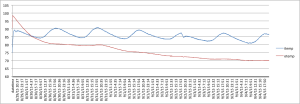

Primary

Target Temperature range: 70F

Average: 76.43F

Standard Deviation: 6.03

9.4.2015 – 1.010 @ 70F – Racked to secondary. Color is near expectations, surprisingly. Very light malty aroma, funk from the Fuggles? Could really do with a dry-hop to bring that aspect out. Tastes light, not much backbone. The malt flavor is there, but with no weight to carry it. Almost no alcohol. Will also need a high level of carbonation. Tobacco on finish? Will dry-hop and see if it can be saved.

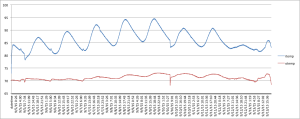

Secondary

Target Temperature range: 70F

Average: 71.25F

Standard Deviation: 0.90

9.9.2015 – Added 1oz Cascade in dry-hop

9.13.2015 – 1.010 @ 70F – Racked to keg. Very hazy beer as it warms, cannot see through it. Not used to that from the extract beers. All cascade flavor and aroma from the dry-hop, orange / citrus. Very light body, did not expect that to change, but needs to be carbonated. Will end up being a drinkable (barely) beer, but needs much more backbone and alcohol to be balanced. Will carbonate at 12.5psi for 2.3vols CO2

Tasting Notes

9.22.2015 – The keg has been on for a few days, and is carbonating. It is getting more drinkable as it carbonates, and is a light, almost session IPA. The dry hop certainly brings out the character – it would be very one-dimensional without it. This beer is good for the work we are doing on the new house, since you can drink a lot of it. That doesn’t mean we’ll try to make it again, though.

9.29.2015 – Updating the notes on this beer. The fermentation did not go well, the very high starting temperature was evident. Beer is quite drinkable once it has carbonated. I expect we will drink a lot of this while moving to our new house this weekend, which is good, because there is a lot left.

Recipe

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.1 gal | 90 min | 45.2 IBUs | 9.0 SRM | 1.062 | 1.015 | 6.2 % |

| Actuals | 1.046 | 1.01 | 4.7 % | |||

Style Details

| Name | Cat. | OG Range | FG Range | IBU | SRM | Carb | ABV |

|---|---|---|---|---|---|---|---|

| American IPA | 14 B | 1.056 - 1.075 | 1.01 - 1.018 | 40 - 70 | 6 - 15 | 2.2 - 2.7 | 5.5 - 7.5 % |

Fermentables

| Name | Amount | % |

|---|---|---|

| Pale Malt (2 Row) US | 11.33 lbs | 93.25 |

| Caramel/Crystal Malt - 60L | 8 oz | 4.12 |

| Pale Malt (2 Row) US (Oven Toasted) | 4 oz | 2.06 |

| Roasted Barley | 1.12 oz | 0.58 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Chinook | 0.75 oz | 90 min | Boil | Pellet | 11.1 |

| Cascade | 0.5 oz | 15 min | Boil | Pellet | 5.7 |

| Fuggles | 0.5 oz | 15 min | Boil | Pellet | 4.2 |

| Cascade | 0.5 oz | 1 min | Boil | Pellet | 5.7 |

| Fuggles | 0.5 oz | 1 min | Boil | Pellet | 4.2 |

Miscs

| Name | Amount | Time | Use | Type |

|---|---|---|---|---|

| Whirlfloc Tablet | 1.00 Items | 15 min | Boil | Fining |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| British Ale Yeast (1098) | Wyeast Labs | 74% | 64°F - 72°F |

Mash

| Step | Temperature | Time |

|---|---|---|

| Mash In | 152°F | 90 min |

Download

| Download this recipe's BeerXML file |

No trackbacks yet.