Harpoon IPA 2

After the session beer that came out of the first batch, I used the same recipe to try and dial in the second batch on the all grain system. It didn’t go so well, either…

Brewer’s Notes

Spent some time going slow and ensuring I hit the main numbers for this batch. 90 minute mash, 90 minute boil. I was also able to get the correct hop bill, which should make me a bit closer. I also sloshed 2gal of mash water before pouring in the grain to try and pre-heat the cooler.

Timeline

1:35p – put water on, 8 gallons at about 70F.

2:48p – mash water to temperature, 163F Mashed in 4.25 gal

3:08p – mash has been going for 20min. Temperature dropped from 154 to 147, and ended at 141F.

4:18p – mash done.

4:40p – Sparge done, took about 20m for a two-step batch sparge. Recirculated about 2qts, then pumped. Added 2gal water, recirc and pump, then added 3gal water, then pump. Boil volume was 7gal. 2.5gal left in HLT.

5:18p – Water at temp, boil started for 90m

6:48p – started chilling. Used 10gal water to chill

7p – Transfer and aeration completed, 1min O2.

In the sparge, the first run was 1.070, second was 1.020, and third was 1.000. Final OG pre-boil was 1.030 at 124F (about – it sat in the test tube for a bit, should have been about 140F). Wort has cereal flavors, fairly sweet, expecting more.

Again, beer is too light in color and taste, but is much better than last attempt. Still not seeing the efficiency or gravity we need. Wondering if it is due to mash temperature and low conversion or sparge issues. Hop balance is better as well, not seeing the same cheesiness from the Fuggles. Outflow temp was pretty warm, the sample tested at 90F. Also ran out of wort, only poured 4.66gal @ 1.044 (90F). Need to increase boil volume to 7.5gal? Set target ferment temp at 70F.

OG: 1.044 @ 90F, target 1.062

FG: 1.0xx @ xxF, target 1.016

Fermenting Notes

Primary

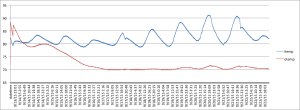

Target Temperature range: 70F

Average: 72.72F

Standard Deviation: 4.11

9.22.2015 – 1.010 @ 72F – Racked to secondary. Color and aroma are good, with a fair bit of small suspended solids – certainly more than we had with extract brews. The beer initially tastes over-bittered, without enough backbone to carry (as expected by the low OG), but it is better than the original batch and is reasonably drinkable coming out of primary, as opposed to the first batch. Still getting sharp, acidic / cheesy from the hops, which becomes less prominent as one drinks the sample. It needs some additional aging and carbonation, and should make a pretty decent beer, if not the target.

Secondary

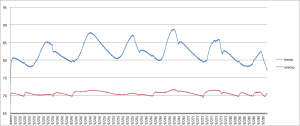

Target Temperature range: 70F

Average: 70.57F

Standard Deviation: 0.49

9.28.2015 – racked to keg. Did not taste beer. Placed on CO2 at 12.5 psi for the remainder of the week, will serve at Oaktoberfest.

Tasting Notes

Recipe

Recipe Details

| Batch Size | Boil Time | IBU | SRM | Est. OG | Est. FG | ABV |

|---|---|---|---|---|---|---|

| 5.1 gal | 90 min | 45.2 IBUs | 9.0 SRM | 1.062 | 1.015 | 6.2 % |

| Actuals | 1.046 | 1.01 | 4.7 % | |||

Style Details

| Name | Cat. | OG Range | FG Range | IBU | SRM | Carb | ABV |

|---|---|---|---|---|---|---|---|

| American IPA | 14 B | 1.056 - 1.075 | 1.01 - 1.018 | 40 - 70 | 6 - 15 | 2.2 - 2.7 | 5.5 - 7.5 % |

Fermentables

| Name | Amount | % |

|---|---|---|

| Pale Malt (2 Row) US | 11.33 lbs | 93.25 |

| Caramel/Crystal Malt - 60L | 8 oz | 4.12 |

| Pale Malt (2 Row) US (Oven Toasted) | 4 oz | 2.06 |

| Roasted Barley | 1.12 oz | 0.58 |

Hops

| Name | Amount | Time | Use | Form | Alpha % |

|---|---|---|---|---|---|

| Chinook | 0.75 oz | 90 min | Boil | Pellet | 11.1 |

| Cascade | 0.5 oz | 15 min | Boil | Pellet | 5.7 |

| Fuggles | 0.5 oz | 15 min | Boil | Pellet | 4.2 |

| Cascade | 0.5 oz | 1 min | Boil | Pellet | 5.7 |

| Fuggles | 0.5 oz | 1 min | Boil | Pellet | 4.2 |

Miscs

| Name | Amount | Time | Use | Type |

|---|---|---|---|---|

| Whirlfloc Tablet | 1.00 Items | 15 min | Boil | Fining |

Yeast

| Name | Lab | Attenuation | Temperature |

|---|---|---|---|

| British Ale Yeast (1098) | Wyeast Labs | 74% | 64°F - 72°F |

Mash

| Step | Temperature | Time |

|---|---|---|

| Mash In | 152°F | 90 min |

Download

| Download this recipe's BeerXML file |

No trackbacks yet.